Description

Features :

Introducing the KCP-E Series with World-First and Industry-First Advanced Technology Built-in.

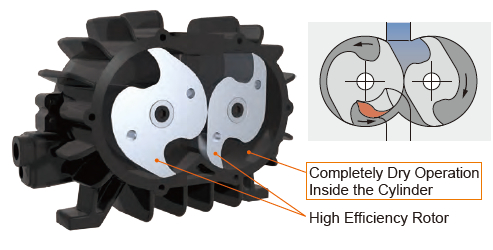

Our newly developed vaneless, no-contact rotor gives vacuum power using less energy. And of course it’s oil-free! Plus, no-contact means even lower noise. Large reduction of harsh low frequency noise (especially 300 Hz and below.)

Using digital analysis technology, we have achieved the optimum curve of our newly developed, high efficiency (non-contact) rotor.

Vacuum pumps create a vacuum by sweeping moving) air out from a particular space. Thanks to our non-contact cylinder construction, the newly developed high efficiency rotor achieves low energy losses. And because the pump is oil-free, it provides economical clean air. In addition, an improved level of maintenance can also be realized.

With ORION’s original temperature reduction technology, we are the first to achieve continuous attainable operation of a 5.5 kW class motor.

A cutting-edge, innovative vacuum pump with three original built-in technologies.

The heat-load problem which was an obstacle to continuous attainable operation was solved by ORION’s original temperature reduction technology. And we succeeded in achieving the world’s first continuous attainable operation with a single-stage claw vacuum pump of the same class.

| Forced Local Cooling | Temperature is significantly reduced by forcibly blowing air near the pump exhaust port, which is the area that generates the greatest amount of heat. |

| Heat-Transfer Reduction Construction | Propagation of heat from the pump cylinder to the gearbox is reduced. |

| Secondary Air Intake | Negative pressure inside the cylinder is used to introduce outside air and cool the pump without increasing power consumption. |

Our high efficiency twin rotor gives a high flow rate using less power.

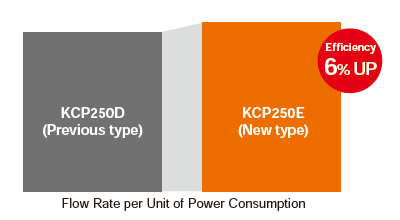

An Evolved High-Efficiency Rotor

Intake Filter: VF30-02

By reviewing the rotor structure of our older KCP250D model, we were able to optimize the contour curves and increase the diameter in the new KCP250E, yielding an efficiency boost of 6%.

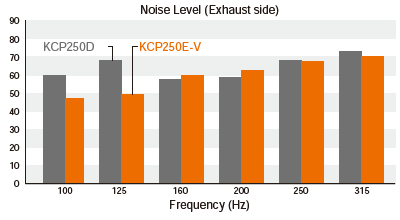

“No-Contact” for Lower Noise. Runs Quieter

Intake Filter: VF100-02

No contact between the cylinder and rotor means reduced and less harsh sounding noise levels. In particular, there is a large reduction of harsh low frequency noise (especially around 300 Hz and below.)

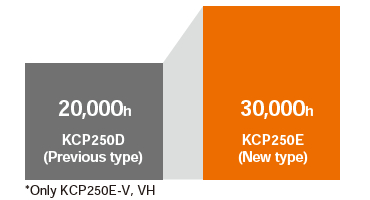

Lower internal loading for a longer product lifespan.

Greatly Extended Overhaul Cycle

Intake Filter: VF30-02

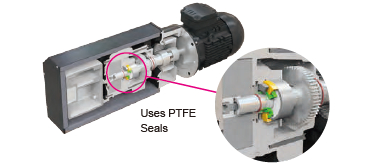

The only consumable part is the sliding seals, so the useful product life time is long.

Oil-Free

Dry slide using PTFE seals. Thanks to our optimized design of sealed parts, our oil-free vacuum pumps and blowers have eliminated oi permeation into the pump room.

Applications :

- Vacuum Forming

- Vacuum Packaging

- Deaeration

- Leak Testing

- Vacuum Cleaning and Drying

- Food Cooling

- Impregnation

- Gas Displacement

- Medical Aspiration

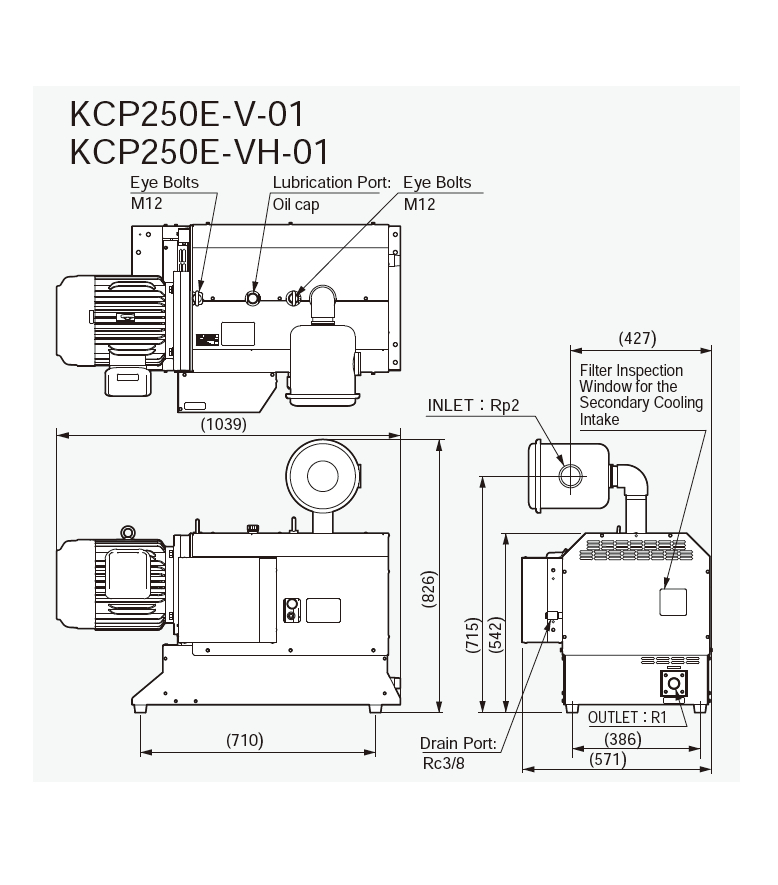

Specification :

| Standard Models | ||||

|---|---|---|---|---|

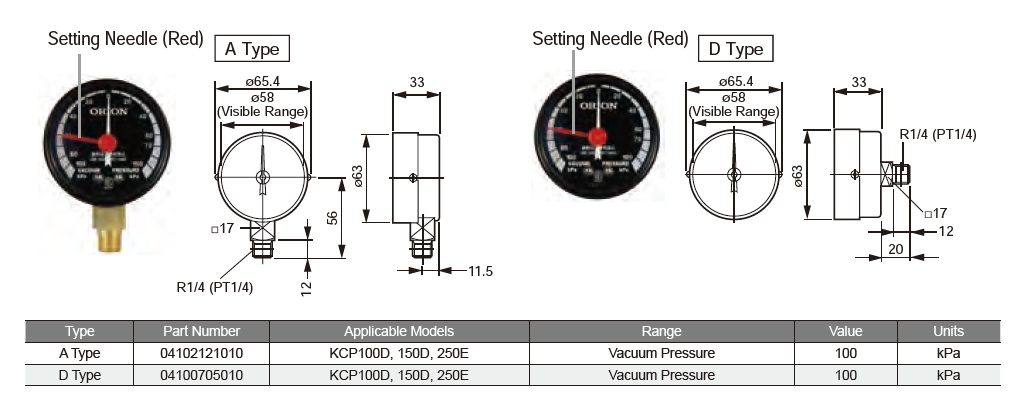

| KCP150D-V-01A | KCP250E-V-01A | |||

| Motor Output | kW | 3.7 | 5.5 | |

| Flow Rate (50/60 Hz) ※1 | m3/h | 158/192 | 256/308 | |

| m3/min | 2.6/3.2 | 4.3/5.1 | ||

| Continuous Opearating Vacuum (50/60 Hz) ※2 | kPa | 0 to 80 | ||

| Ultimate Degree of Vacuum (50/60 Hz) ※2 | kPa | 90/94 kPa or Higher | ||

| Operating Noise Level (50/60 Hz) ※3 | dB | 76/78 | 78/80 | |

| Piping Connection Size | Rp1 1/2 | Rp2 | ||

| Mass | kg | 155 | 253 | |

| Motor | Rated Voltage And Frequency ※4 | Three-phase 200 V – 50/60 Hz, 220 V – 60 Hz | ||

| Output, Number of Units | 3.7 kW / 2P × 1 Unit | 5.5 kW / 2P × 1 Unit | ||

| Specifications | Top Runner compliant, high efficiency motor | |||

| Working Environment | Place of installation | Indoors | ||

| Allowable Ambient Temperature ※5 | ℃ | 0 to 40 | ||

| Allowable Ambient Humidity | 65 ± 20%RH (JIS Z8703) | |||

| Operable Elevation ※6 | m | 1000 or lower | ||

| Accessory (Sold Separately) | Hour Meter / Intake Filter | |||

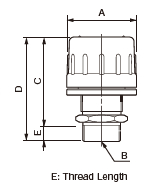

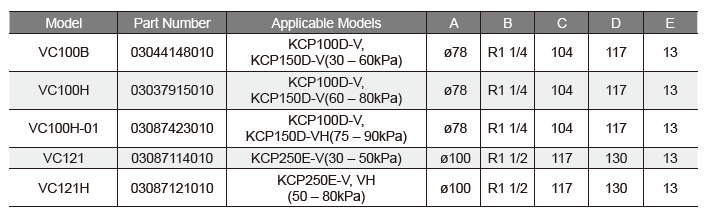

| Optional Equipment | Vacuum controller, Pressure gauge, Casters | |||

| Inverter Control | Possible | |||

| Recommended Overhaul Cycle | h | 20000 | 30000 | |

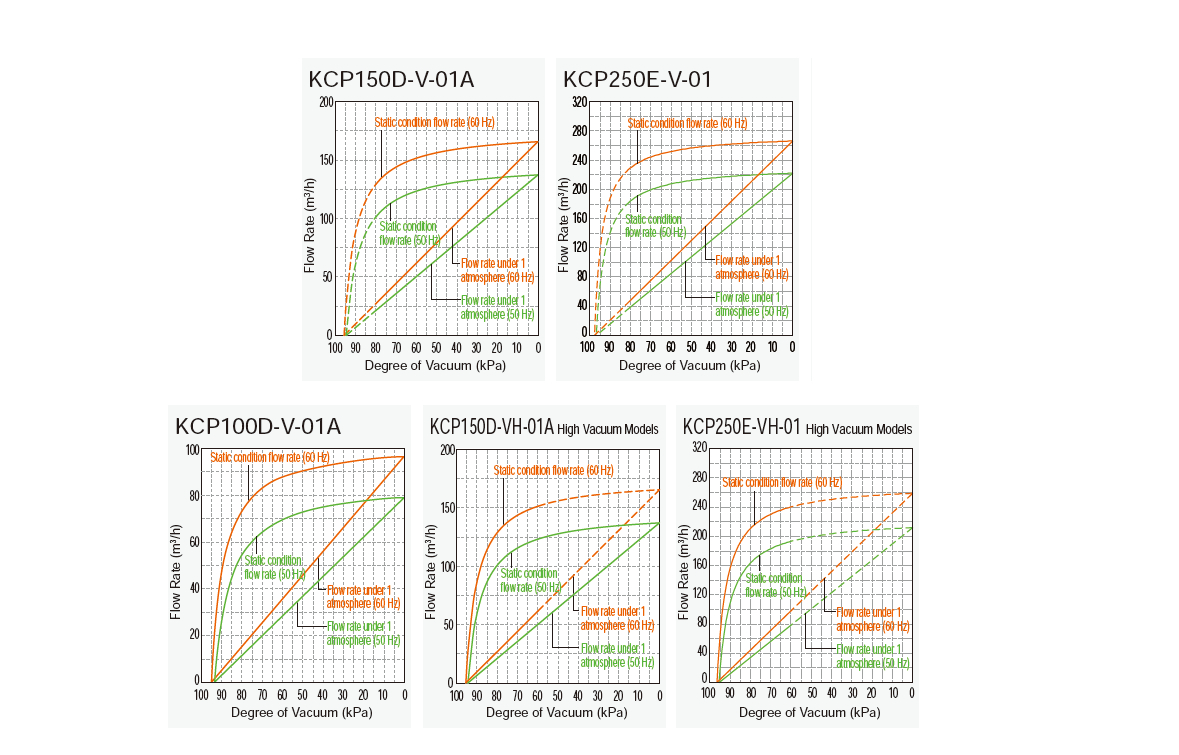

- This is the designed flow rate based on the cylinder volume of the pump. Confirm the actual flow rate based on the pressure-flow diagram.

- Under ambient pressure of 1 atm. When operating at high elevations, there will be a difference in operating pressure from operation at a location under 1 atm of pressure. The calculation to measure the ultimate vacuum while operating at other elevations is as follows: Ultimate Vacuum Under Pressure (simplified) [kPa] = Specified Ultimate Degree of Vacuum [kPa] – Altitude [m] * 0.0115 [kPa/m ]

- Noted operating noise level is when using an ORION motor. Operating noise measured at on operating vacuum of 80 kPa, and is not a guaranteed value.

- The power supply voltage must not have intermittent fluctuations greater than 10%, or 5% if fluctuations are continued.

- If the pump is started where the ambient temperature is around 0℃, a high frequency noise may be heard. The noise will naturally go away in a short time and does not indicate abno noise continues for more than 30 minutes, consult with your dealer or a qualified repair person.

- Please consult with ORION if the product is to be operated at an elevation above 1000 m.

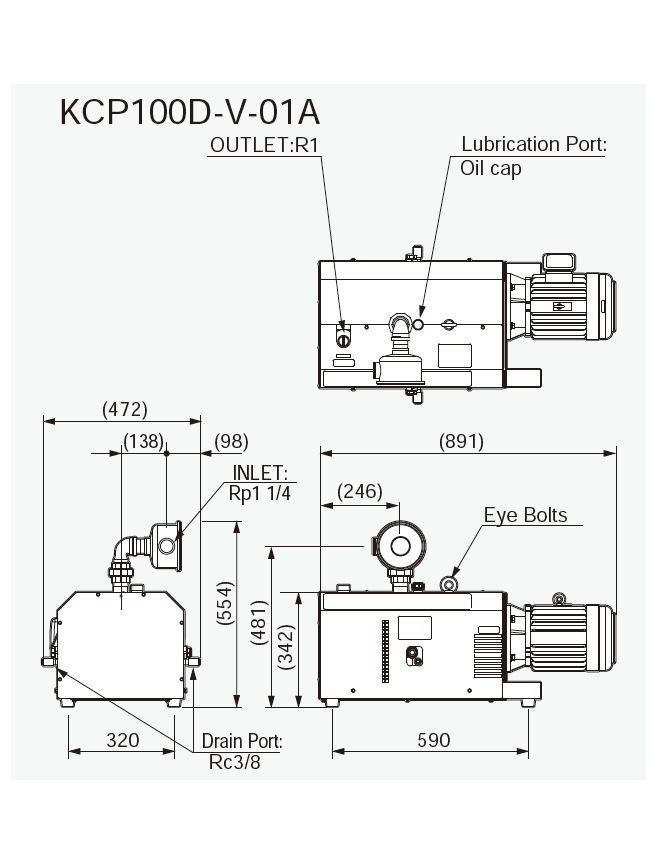

| High Vacuum Models | |||||

|---|---|---|---|---|---|

| KCP100D-V-01A | KCP150D-VH-01A | KCP250E-VH-01 | |||

| Motor Output | kW | 2.2 | 3.7 | 5.5 | |

| Flow Rate (50/60 Hz) ※1 | m3/h | 96/117 | 158/192 | 256/308 | |

| m3/min | 1.6/2.0 | 2.6/3.2 | 4.3/5.1 | ||

| Continuous Opearating Vacuum (50/60 Hz) ※2 | kPa | 0 to ultimate vacuum | 60 to ultimate vacuum | 60 to ultimate vacuum | |

| Ultimate Degree of Vacuum (50/60 Hz) ※2 | kPa | 90/94 or Higher | |||

| Operating Noise Level (50/60 Hz) ※3 | dB | 74/76 | 78/82 | 80/81 | |

| Piping Connection Size | Rp1 1/4 | Rp1 1/2 | Rp2 | ||

| Mass | kg | 135 | 155 | 253 | |

| Motor | Rated Voltage And Frequency ※4 | Three-phase 200 V – 50/60 Hz, 220 V – 60 Hz | |||

| Output, Number of Units | 2.2 kW・2P × 1 Unit | 3.7 kW・2P × 1 Unit | 5.5 kW・2P × 1 Unit | ||

| Specifications | Top Runner compliant, high efficiency motor | ||||

| Working Environment | Place of installation | Indoors | |||

| Allowable Ambient Temperature ※5 | ℃ | 0 to 40 | |||

| Allowable Ambient Humidity | 65 ± 20%RH (JIS Z8703) | ||||

| Operable Elevation ※6 | m | 1000 or lower | |||

| Accessory (Sold Separately) | Hour meter / Intake filter | ||||

| Optional Equipment | Vacuum controller, Pressure gauge, casters | ||||

| Inverter Control | Possible | ||||

| Recommended Overhaul Cycle | h | 20000 | 20000 | 30000 | |

- This is the designed flow rate based on the cylinder volume of the pump. Confirm the actual flow rate based on the pressure-flow diagram.

- Under ambient pressure of 1 atm. When operating at high elevations, there will be a difference in operating pressure from operation at a location under 1 atm of pressure. The calculation to measure the ultimate vacuum while operating at other elevations is as follows: Ultimate Vacuum Under Pressure (simplified) [kPa] = Specified Ultimate Degree of Vacuum [kPa] – Altitude [m] * 0.0115 [kPa/m ]

- Noted operating noise level is when using an ORION motor. Operating noise measured at on operating vacuum of 80 kPa, and is not a guaranteed value.

- The power supply voltage must not have intermittent fluctuations greater than 10%, or 5% if fluctuations are continued.

- If the pump is started where the ambient temperature is around 0℃, a high frequency noise may be heard. The noise will naturally go away in a short time and does not indicate abno noise continues for more than 30 minutes, consult with your dealer or a qualified repair person.

- Please consult with ORION if the product is to be operated at an elevation above 1000 m.